Your cart is currently empty!

Category: 3D printing

-

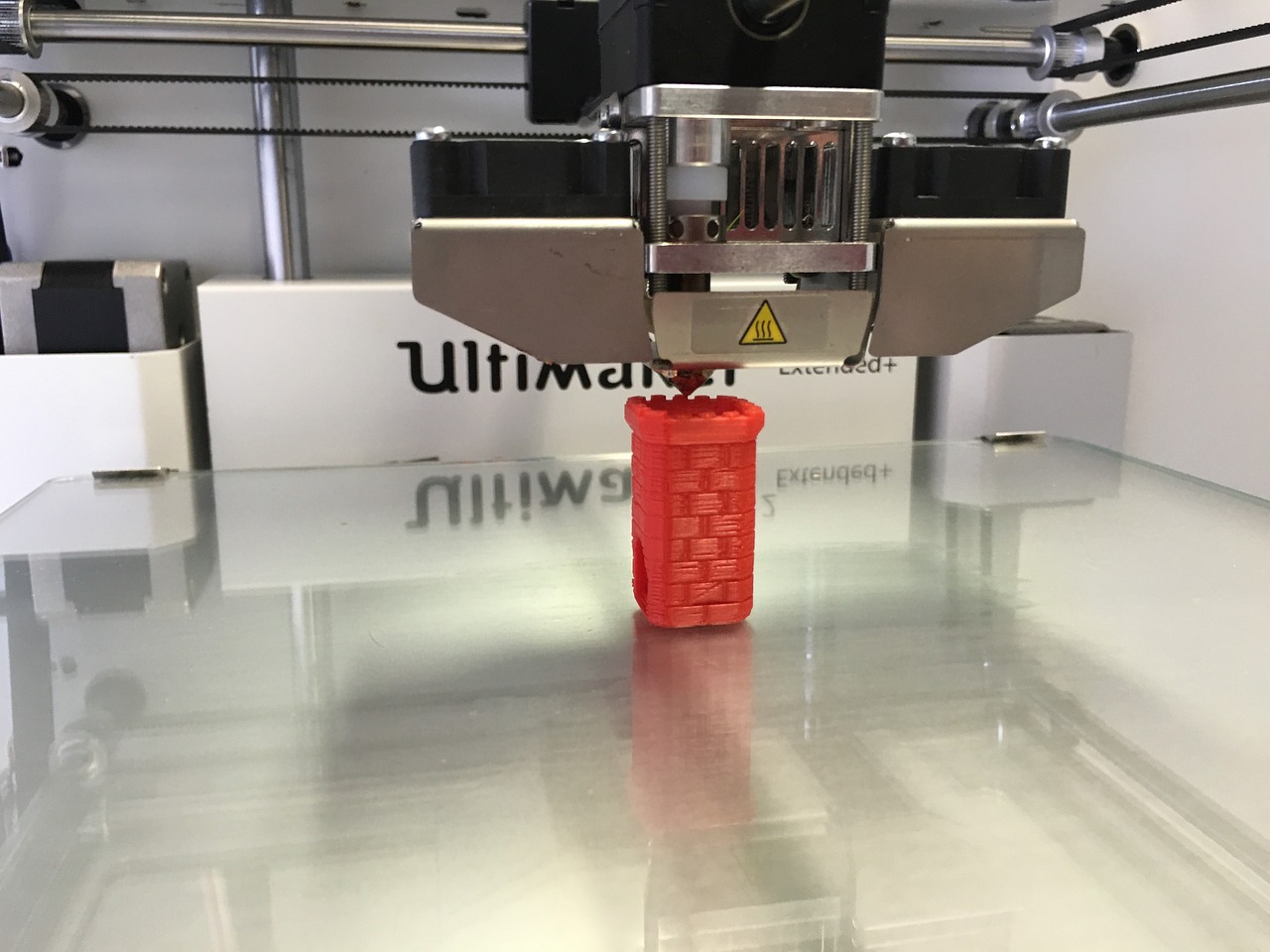

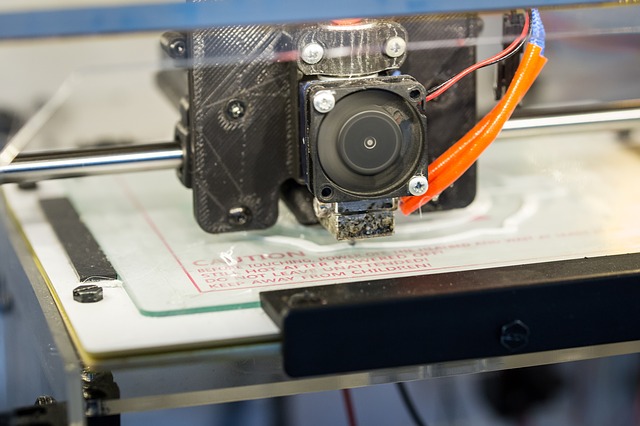

How 3D Printing is changing the World of Manufacturing?

3D printing, also known as additive manufacturing, is a technology that has been rapidly advancing in recent years. This technology allows for the creation of three-dimensional objects by building up layers of material, making it possible to produce a wide range of products quickly and efficiently. The rise of 3D printing is transforming the world…

-

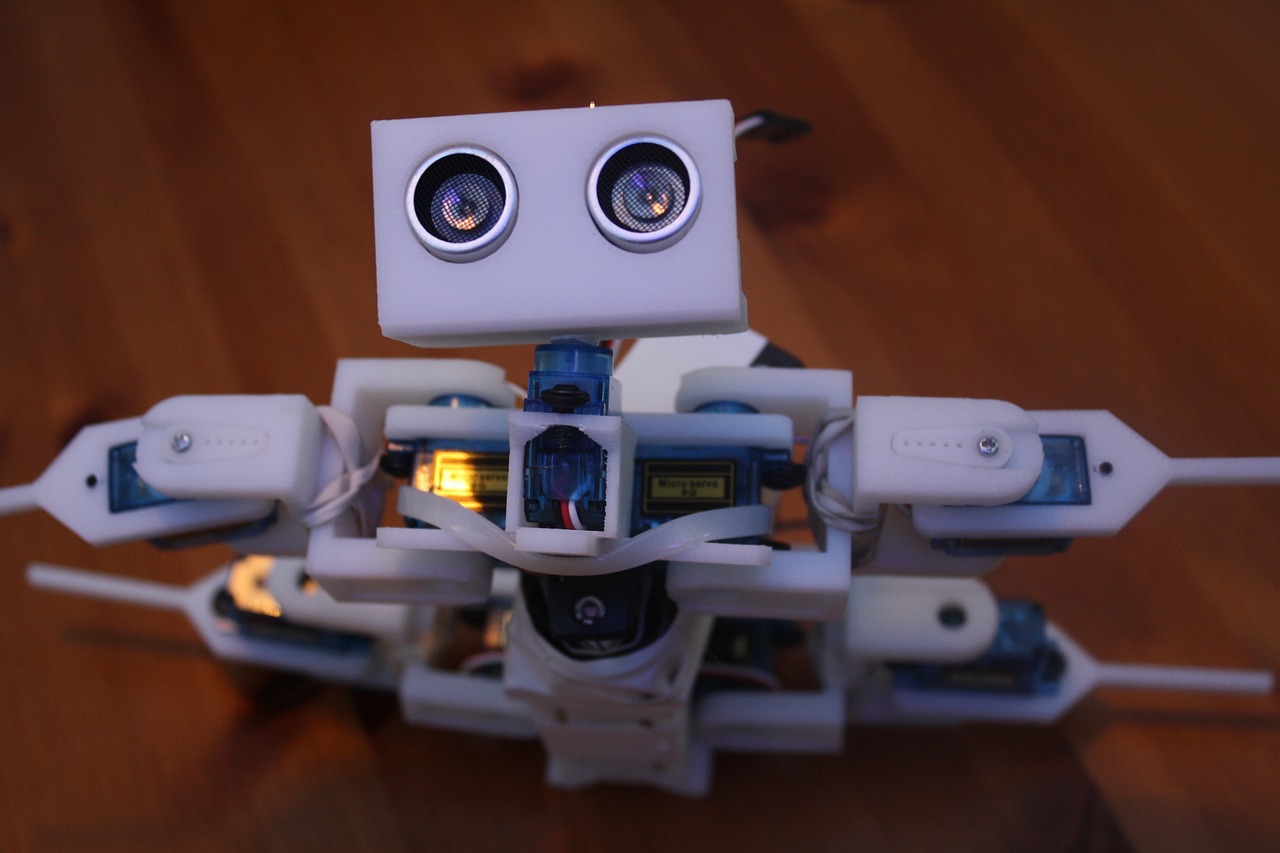

What is the most Profitable Thing to 3D Print?

3D printing has become a popular technology for creating a wide range of products, from toys to complex machinery. With the rise of this technology, many people are looking for ways to profit from it. The profitability of a 3D printing project can depend on several factors, such as the cost of materials, the time…

-

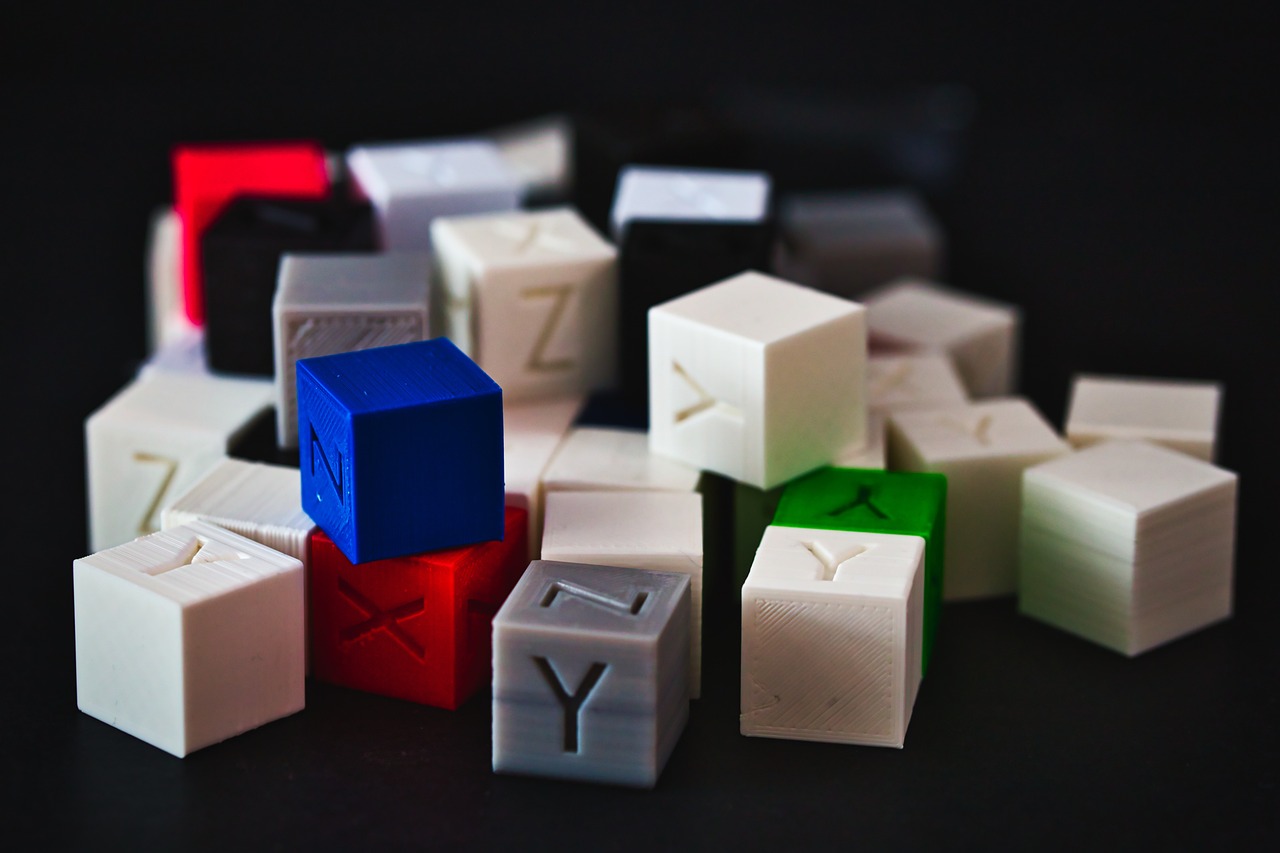

What are 5 Materials you can use to 3D Print?

3D printing has revolutionized the manufacturing industry by providing a fast, cost-effective, and versatile means of producing complex, functional objects. One of the key factors in determining the success of a 3D printing project is the material used. With a wide range of 3D printing materials available, it can be challenging to determine which one…

-

What is the most important 3D Printing Material?

There are several different types of 3D printing materials available, each with its own unique properties and characteristics. Some of the most commonly used 3D printing materials include: Plastics Plastics are one of the most commonly used 3D printing materials due to their versatility and affordability. There are several different types of plastics used in…

-

What Considerations must you make when choosing a 3D Printing Technology?

3D printing technology has come a long way since its inception, and the number of available options has increased significantly. With so many options to choose from, it can be difficult to determine which one is best for your needs. When choosing a 3D printing technology, there are several important considerations to keep in mind…