Your cart is currently empty!

Epson Error Code 0xF5: Waste Ink Pad Counter Overflow [How to Fix]

Error codes can be a cause of concern for printer users, especially…

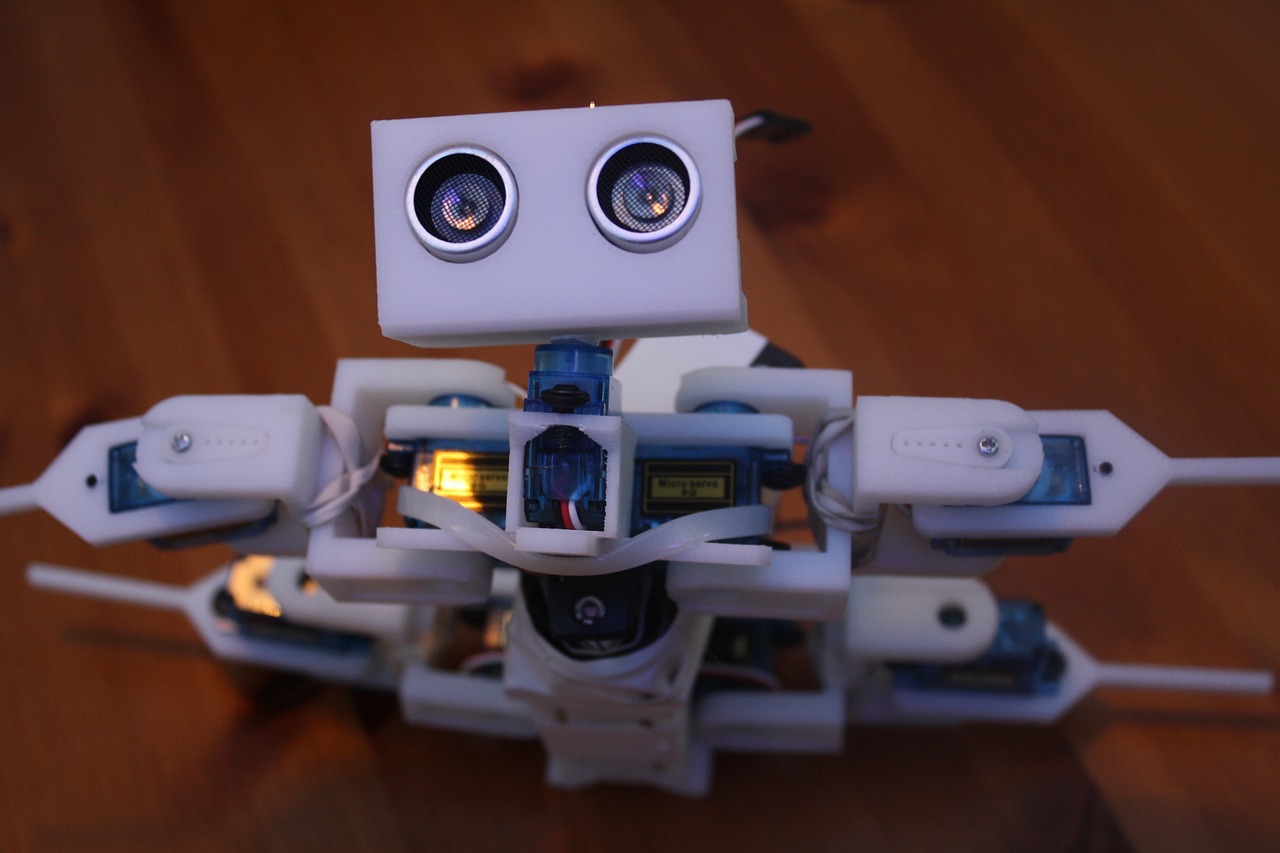

3D printing, also known as additive manufacturing, is a technology that has been rapidly advancing in recent years. This technology allows for the creation of three-dimensional objects by building up layers of material, making it possible to produce a wide range of products quickly and efficiently. The rise of 3D printing is transforming the world of manufacturing, making it possible to produce products faster, cheaper, and more accurately. In this article, we will explore how 3D printing is changing the world of manufacturing and what this means for businesses and consumers alike.

One of the most significant ways that 3D printing is changing the world of manufacturing is by reducing lead times. With traditional manufacturing methods, it can take months or even years to produce a product, especially if the product is complex or requires a large number of parts. With 3D printing, it is possible to produce products in a matter of hours or days, making it possible to bring products to market faster and more efficiently.

Reduced lead times also means that product development can be faster with 3D printing. With traditional manufacturing methods, it can take months or even years to develop a product, as each iteration requires the creation of new prototypes and the testing of those prototypes. With 3D printing, it is possible to produce prototypes quickly and efficiently, making it possible to iterate on designs faster and get products to market more quickly.

Reduced lead times also mean that businesses can respond more quickly to market demand. With traditional manufacturing methods, it can take months or even years to produce a product, which makes it difficult for businesses to respond to market changes or shifts in consumer demand. With 3D printing, it is possible to produce products in a matter of hours or days, making it possible for businesses to respond to market changes more quickly and efficiently.

Another way that 3D printing is changing the world of manufacturing is by lowering costs. With traditional manufacturing methods, the cost of producing a product can be high, especially if the product is complex or requires a large number of parts. With 3D printing, the cost of producing a product can be significantly lower, as there is no need for expensive tooling or molds.

Lower costs also mean that the cost of materials can be lower with 3D printing. With traditional manufacturing methods, the cost of materials can be high, especially if the product is complex or requires a large number of parts. With 3D printing, the cost of materials can be significantly lower, as it is possible to produce products using less material, making it a more environmentally friendly and cost-effective option.

Lower costs also mean that the cost of production can be lower with 3D printing. With traditional manufacturing methods, the cost of production can be high, especially if the product is complex or requires a large number of parts. With 3D printing, the cost of production can be significantly lower, as it is possible to produce products more quickly and efficiently, making it a more cost-effective option.

by

Tags:

Error codes can be a cause of concern for printer users, especially…

Error codes can be a frustrating roadblock when you’re trying to print…

Printers are essential devices for both home and office use, but encountering…

As convenient as printers are, encountering error codes can be a frustrating…

Error codes are a common occurrence with printers, and one such error…

Printers are essential tools for our daily work, but encountering errors can…