Your cart is currently empty!

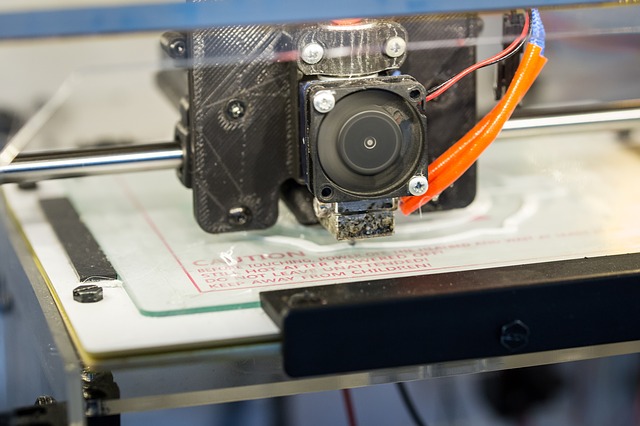

What Considerations must you make when choosing a 3D Printing Technology?

3D printing technology has come a long way since its inception, and the number of available options has increased significantly. With so many options to choose from, it can be difficult to determine which one is best for your needs. When choosing a 3D printing technology, there are several important considerations to keep in mind to ensure that you select the right one for your project.

Types of 3D Printing Technologies

There are several different types of 3D printing technologies available, each with its own unique strengths and weaknesses. Some of the most commonly used 3D printing technologies include:

Fused Deposition Modeling (FDM)

Fused Deposition Modeling, also known as Fused Filament Fabrication (FFF), is one of the most commonly used 3D printing technologies. This technology works by heating a thermoplastic filament and depositing it layer by layer to build up the desired object. FDM is best suited for producing functional prototypes and low-volume production runs, as the finished objects are relatively strong and can withstand some stress.

Stereolithography (SLA)

Stereolithography is a 3D printing technology that uses a UV laser to cure resin layer by layer, forming the desired object. This technology is best suited for producing high-resolution objects with fine details, as the laser can cure the resin precisely. However, the finished objects can be brittle, so they may not be suitable for functional prototypes or low-volume production runs.

Digital Light Processing (DLP)

Digital Light Processing is a variation of Stereolithography that uses a digital light projector instead of a UV laser to cure the resin. This technology is also best suited for producing high-resolution objects with fine details, and it has the advantage of being able to cure the resin much faster than SLA. However, like SLA, the finished objects can be brittle.

Selective Laser Sintering (SLS)

Selective Laser Sintering is a 3D printing technology that uses a laser to heat and fuse together particles of nylon powder, layer by layer, to build up the desired object. This technology is best suited for producing strong, durable objects, as the nylon material is relatively strong and can withstand some stress. However, SLS objects can be more expensive to produce, as the nylon powder is relatively expensive.

Material Considerations

One of the most important considerations when choosing a 3D printing technology is the type of material that you need to use. Different 3D printing technologies are best suited for different types of materials, and some technologies are limited to specific types of materials. When choosing a 3D printing technology, it is important to consider the following factors:

Availability

The availability of materials is an important consideration when choosing a 3D printing technology. Some technologies are limited to specific types of materials, while others are more flexible. If you have a specific material in mind for your project, it is important to ensure that the technology you choose is compatible with that material.

Strength and Durability

The strength and durability of the finished object is also an important consideration when choosing a 3D printing technology. Different materials have different strengths and weaknesses, and some technologies produce objects that are stronger and more durable than others. When choosing a 3D printing technology, it is important to consider the intended use of the finished object and select a material that is appropriate for that use.

Cost

The cost of the material is another important consideration when choosing a 3D printing technology. Some materials can be relatively expensive, while others are more affordable. It is important to consider the cost of the material when selecting a 3D printing technology, as this can have a significant

by

Tags: