Your cart is currently empty!

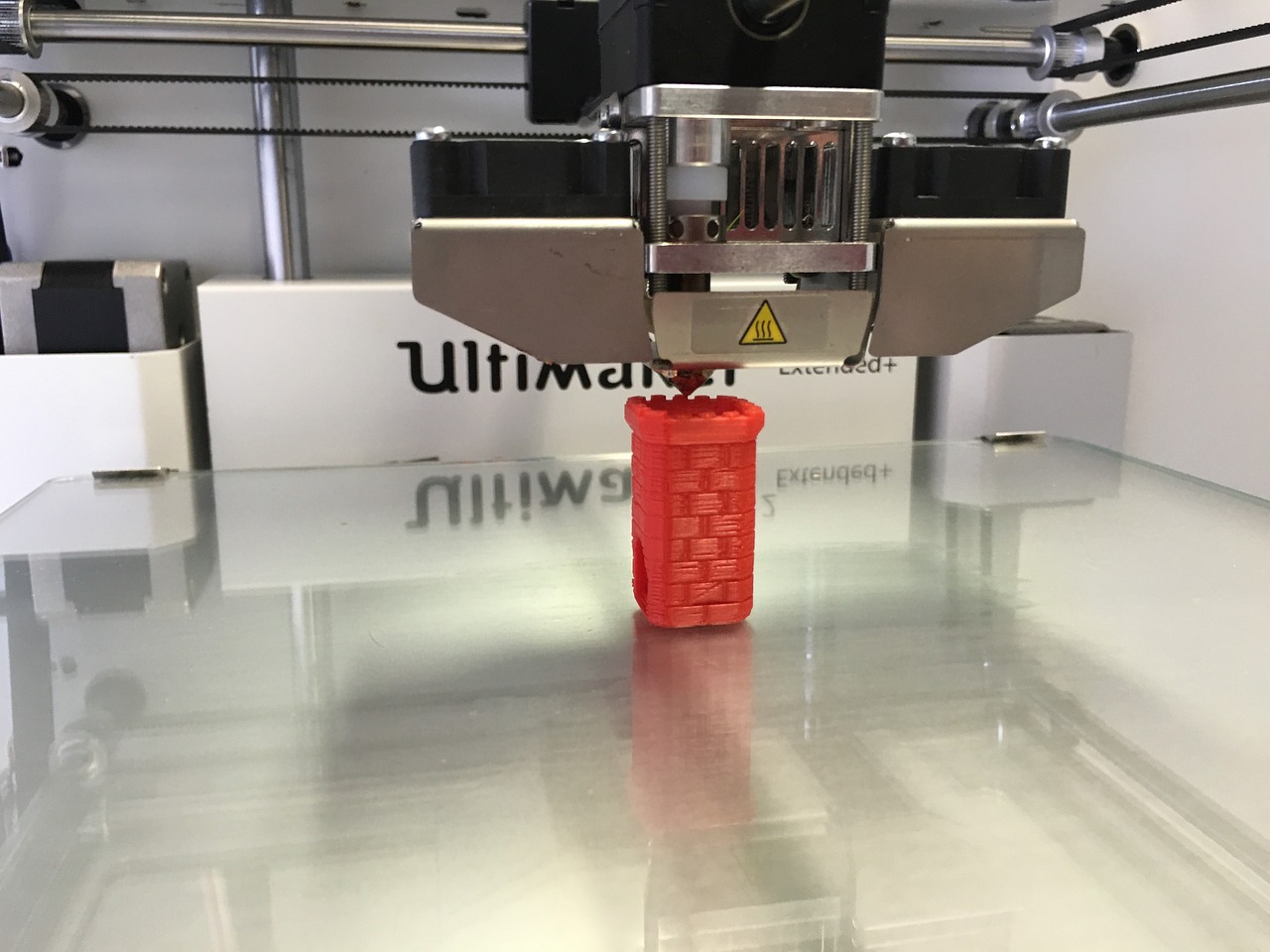

What is the most Profitable Thing to 3D Print?

3D printing has become a popular technology for creating a wide range of products, from toys to complex machinery. With the rise of this technology, many people are looking for ways to profit from it. The profitability of a 3D printing project can depend on several factors, such as the cost of materials, the time required to produce the product, and the demand for the product. In this article, we will explore some of the most profitable things to 3D print and what makes them so profitable.

1. Customized Products

Customized products are one of the most profitable things to 3D print due to the growing demand for unique and personalized products. From custom phone cases to personalized jewelry, there is a huge market for customized products. With 3D printing, it is possible to create unique and intricate designs that would be difficult or impossible to produce using traditional manufacturing methods.

Customized Phone Cases

Customized phone cases are a popular and profitable product to 3D print. They are relatively small and easy to produce, and there is a high demand for them due to the growing popularity of smartphones. With 3D printing, it is possible to create custom phone cases with intricate designs and personalization, which can increase their value and profitability.

Customized Jewelry

Customized jewelry is another popular and profitable product to 3D print. With 3D printing, it is possible to create intricate designs that would be difficult or impossible to produce using traditional manufacturing methods. Customized jewelry can be produced at a lower cost compared to traditional manufacturing methods, making it a profitable product to 3D print.

2. Replacement Parts

Replacement parts are another profitable product to 3D print. With the increasing complexity of modern machinery, there is a growing demand for replacement parts that are difficult or impossible to find. With 3D printing, it is possible to produce these parts quickly and at a lower cost compared to traditional manufacturing methods.

Replacement Parts for Outdated Machinery

Outdated machinery can be expensive and time-consuming to repair, especially if the replacement parts are difficult or impossible to find. With 3D printing, it is possible to produce replacement parts quickly and at a lower cost, which can save businesses time and money.

Replacement Parts for Rare or Discontinued Products

Replacement parts for rare or discontinued products can be difficult or impossible to find, which can make it expensive and time-consuming to repair these products. With 3D printing, it is possible to produce replacement parts quickly and at a lower cost, which can increase the lifespan of these products and save businesses money.

3. Prototypes

Prototypes are another profitable product to 3D print. With the fast and cost-effective nature of 3D printing, it is possible to produce prototypes quickly and at a lower cost compared to traditional manufacturing methods. This can save businesses time and money, as they can test their designs and make changes more quickly and efficiently.

Product Prototypes

Product prototypes are an important part of the product development process, as they allow businesses to test and refine their designs before producing the final product. With 3D printing, it is possible to produce prototypes quickly and at a lower cost compared to traditional manufacturing methods, which can save businesses time and money.

Architectural Prototypes

Architectural prototypes are also an important part of the architectural design process, as they allow architects to test and refine their designs before construction begins. With 3D printing, it is possible to produce architectural prototypes quickly and at a lower cost compared to traditional manufacturing methods, which can save architects time and money.

by

Tags: