Nowadays everyone is 3D Printing Objects with their 3D printers and some are doing it for hobby purposes and some are doing it for business, but as we move forward and the technology advances more and more we can see that there are many types of filaments now to print on such as: Wood Infill, Bronze Infill, Silver Infill, PLA, ABS, Nylon and PETG. So today we will experiment with PETG and see if it’s a good filament or not.

PETG FILAMENT PRO AND CONS

| PROS | CONS |

| Very easy to sand | High Printing Temperature 245c + |

| Smooth surface | Not much brand options |

| Very Flexible | Sticky and stringing problems |

| Very strong | High bed temperature: 70c + |

| Lower risk of warping | Might damage nozzles made of brass because of high printing temperature |

| Low shrinkage |

PETG filament can be very useful depending on your requirement, one of the best advantage of this filament is that it has low shrinkage and its very easy to sand and very strong. Unlike PLA filament If you bend a part made of PLA it will split in 2 parts when applied with force but with PETG it will bend and return to it’s original position.

Price comparison

PETG Filament is cheap just like the other filaments you can find 1KG roll for about $30 to $40 depending on the brand.

Order yours below:

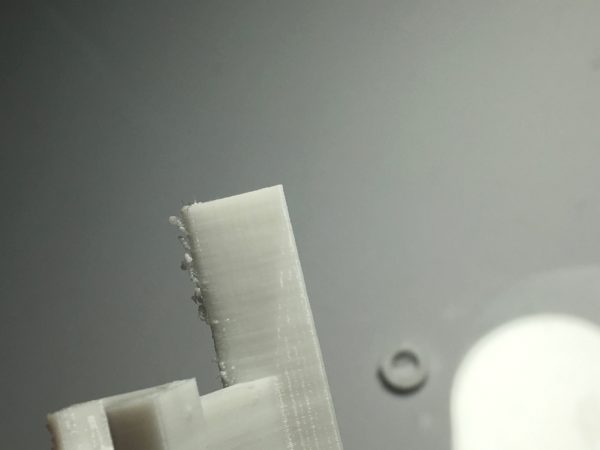

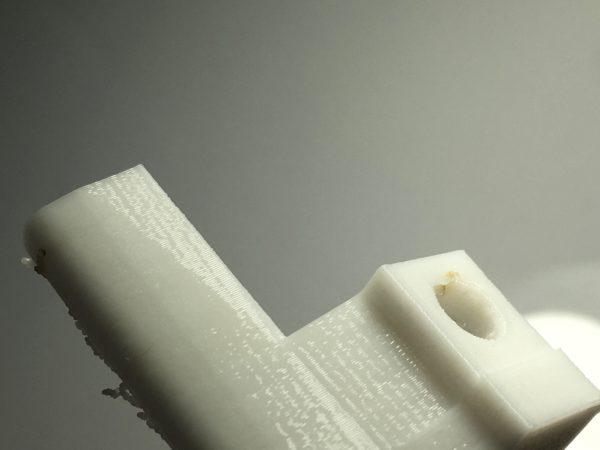

Print tests

Below is some print tested made with PETG filament, the settings used are as follow:

- Nozzle Temperature: 250c

- Bed Temperature: 83c

- Speed: 60mm / sec

- Resolution: 0.15

- Infill: 100%

When PETG Should be used

You can use this filament when you need robust strength and some flexibility like: cases, Corner brackets, Motor adapters and anything that needs good strength and a higher temperature resistance.

When you shouldn’t use it

PETG filament can be great for certain uses but in some cases you shouldn’t use it when you need precise parts or need sharp details, this is a very sticky filament and your prints will come out with more round edges and less details because of this, if you need high detail PLA is the best choice.

Another time you shouldn’t PETG is when you’re printing something very small, the filament will not cool down enough before the next filament is laid down and will start getting sticky and probably detach from the base or will stick to the nozzle even with cooling fans at 100%.